Exploring the World of Specialty Pipe and Tube: A Comprehensive Guide

When it comes to pipes and tubes, most people think of the standard cylindrical structures used for plumbing or construction. However, there is a whole world of specialty pipe and tube products that serve unique purposes and require specialized manufacturing processes.

In this comprehensive guide, we will explore the world of specialty pipe and tube, including what they are, how they are made, and the industries that rely on them.

What Are Specialty Pipe and Tube?

Specialty pipe and tube refer to pipes and tubes that are designed for specific purposes and require specialized manufacturing processes. These products are often made from materials such as steel, aluminum, or titanium and can come in a variety of shapes and sizes.

Types of Specialty Pipe and Tube

There are many different types of specialty pipe and tube, each with its own unique characteristics and uses.

Some of the most common types include:

Heat Exchanger Tubes:

These tubes are used to transfer heat between two fluids, making them essential in industries such as power generation, chemical processing, and HVAC.

Boiler Tubes:

Boiler tubes are used in high-pressure boilers to carry steam or water, making them crucial for power generation and industrial processes.

Mechanical Tubes:

These tubes are used in mechanical and structural applications, such as in the automotive, construction, and agricultural industries.

Oil Country Tubular Goods (OCTG):

OCTG refers to a range of products used in the oil and gas industry, including casing, tubing, and drill pipes.

Pressure Tubing:

Pressure tubing is designed to withstand high pressures and is used in applications such as hydraulic systems, pressure vessels, and heat exchangers.

Specialty Shapes:

Specialty shapes refer to pipes and tubes that are not round, such as square, rectangular, or oval tubes. These products are often used in architectural, decorative, or structural applications.

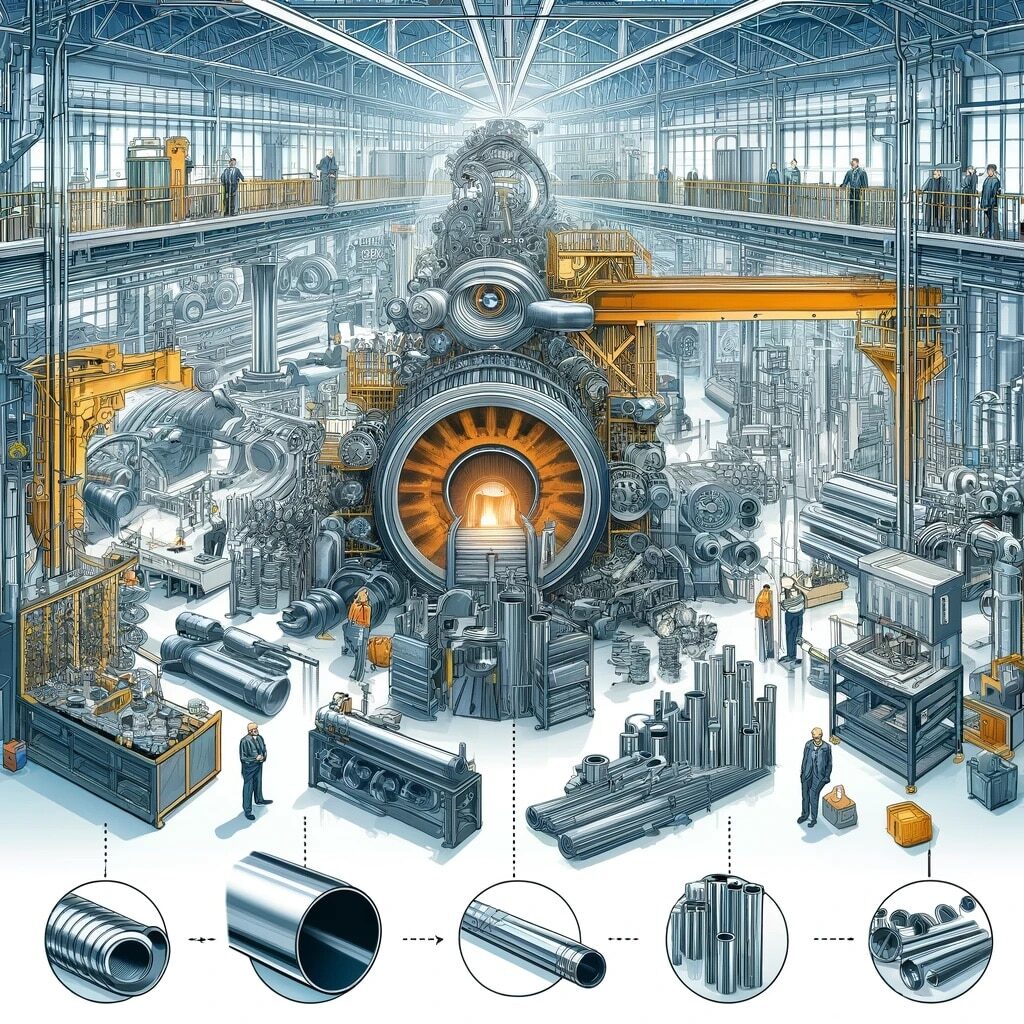

How Are Specialty Pipe and Tube Made?

The manufacturing process for specialty pipe and tube varies depending on the type of product and the material used. However, there are some common steps involved in the production of most specialty pipes and tubes.

Step 1: Material Selection

The first step in making specialty pipe and tube is selecting the appropriate material. This decision is based on the intended use of the product, as different materials have different properties and strengths.

For example, steel is a popular choice for mechanical tubes due to its strength and durability, while aluminum is often used for heat exchanger tubes due to its excellent thermal conductivity.

Step 2: Forming

Once the material has been selected, it is then formed into the desired shape. This can be done through various processes, such as hot or cold rolling, extrusion, or welding.

For example, mechanical tubes are often made through the process of hot rolling, where a heated billet of steel is passed through a series of rollers to form the desired shape.

Step 3: Heat Treatment

After forming, the pipes and tubes may undergo a heat treatment process to improve their strength and durability. This involves heating the product to a specific temperature and then cooling it at a controlled rate.

Step 4: Finishing

The final step in the manufacturing process is finishing, which involves cleaning, cutting, and inspecting the product. This ensures that the pipes and tubes meet the required specifications and are free from any defects.

Industries That Rely on Specialty Pipe and Tube

Specialty pipe and tube are used in a wide range of industries, each with its own unique needs and requirements.

Some of the most common industries that rely on these products include:

Oil and Gas Industry

The oil and gas industry is one of the largest consumers of specialty pipe and tube products. These products are used in various applications, such as drilling, production, and transportation of oil and gas.

Deeper Dive: Click here to learn more about the Oil and Gas Industry

Power Generation Industry

Specialty pipe and tube are essential in the power generation industry, where they are used in boilers, heat exchangers, and other critical components. These products must be able to withstand high temperatures and pressures to ensure the safe and efficient production of electricity.

Deeper Dive: Click here to learn more about the Power Generation Industry

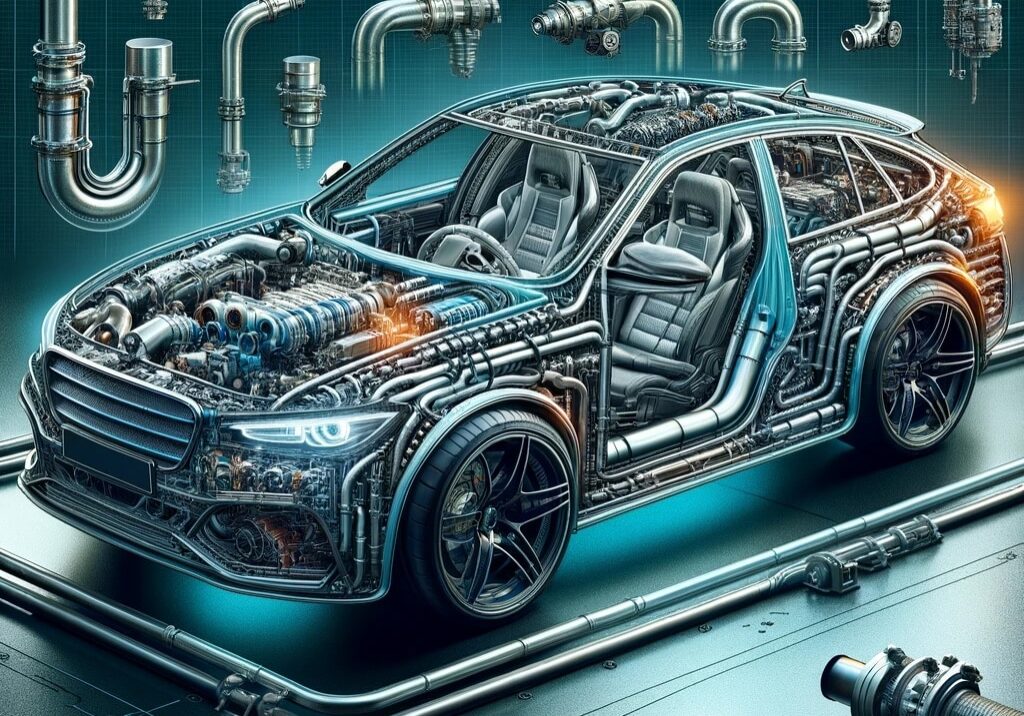

Automotive Industry

The automotive industry also relies on specialty pipe and tube for various applications, such as exhaust systems, fuel lines, and structural components. These products must meet strict standards for strength, durability, and corrosion resistance.

Deeper Dive:

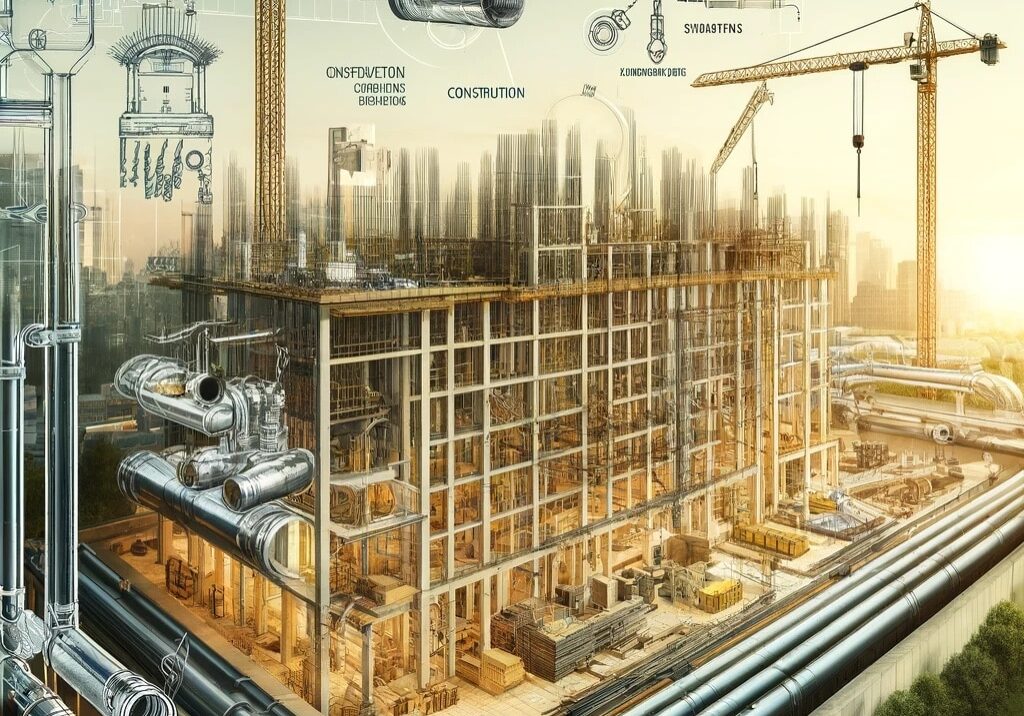

Construction Industry

Specialty pipe and tube are used in the construction industry for a variety of purposes, such as structural support, plumbing, and HVAC systems. These products must be able to withstand heavy loads and harsh environmental conditions.

Deeper Dive:

Aerospace Industry

The aerospace industry also relies on specialty pipe and tube for various applications, such as aircraft frames, landing gear, and hydraulic systems. These products must meet strict standards for strength, weight, and corrosion resistance.

Case Study: How Federal Steel Supply Met and Exceeded NASA’s Specialty Steel Pipe and Tube Needs

Custom Fabrication of Specialty Pipe and Tube

In addition to standard specialty pipe and tube products, many manufacturers also offer custom fabrication services. This allows customers to order products that are tailored to their specific needs and requirements.

Custom fabrication involves working closely with the customer to understand their needs and then designing and manufacturing a product that meets those needs.

This can include creating unique shapes, sizes, and materials to ensure the product is fit for purpose.

Specialty Pipe and Tube: The Future

As technology continues to advance, the demand for specialty pipe and tube is expected to grow. This is particularly true in industries such as renewable energy, where specialty pipes and tubes are used in applications such as wind turbines and solar panels.

Additionally, as the world becomes more environmentally conscious, there is a growing demand for sustainable and energy-efficient products. This is driving the development of new specialty pipe and tube products that are lighter, stronger, and more durable.

Key Takeaways

Specialty pipe and tube play a crucial role in many industries, from oil and gas to construction and aerospace. These products are designed for specific purposes and require specialized manufacturing processes to ensure they meet the required standards.

As technology continues to advance, the demand for specialty pipe and tube is expected to grow, making it an exciting and ever-evolving industry to watch.

With Federal Steel Supply's custom fabrication services, customers can order products that are tailored to their specific needs, ensuring the success of their projects.

Take a Deeper Dive:

- Services: Machining, Cutting & Custom Bevels

- Services: Custom Surfaces & Coatings

- Deeper Dive: Explore how Federal Steel Supply serves the Fabrication Industry