Introduction to ASTM Standards

Importance of ASTM Standards in Industrial Procurement

In the complex world of industrial procurement, understanding ASTM standards for steel tubes and pipes is crucial for ensuring quality, reliability, and compliance. These standards provide a framework for material specifications, testing methods, and quality assurance, helping procurement managers, engineers, and project managers make informed decisions.

Overview of ASTM Standards for Steel Tubes and Pipes

ASTM standards for steel tubes and pipes cover a wide range of specifications, each identified by a unique code. These standards detail the type of steel pipe or tube, mechanical properties, and specific applications, ensuring that materials meet the required performance criteria.

Key ASTM Standards for Steel Tubes and Pipes

ASTM A53/A53M-02

Applications and Uses

ASTM A53/A53M-02 covers black and hot-dipped, zinc-coated, welded, and seamless steel pipes. These pipes are widely used in the construction of oil and gas pipelines, water systems, and structural applications.

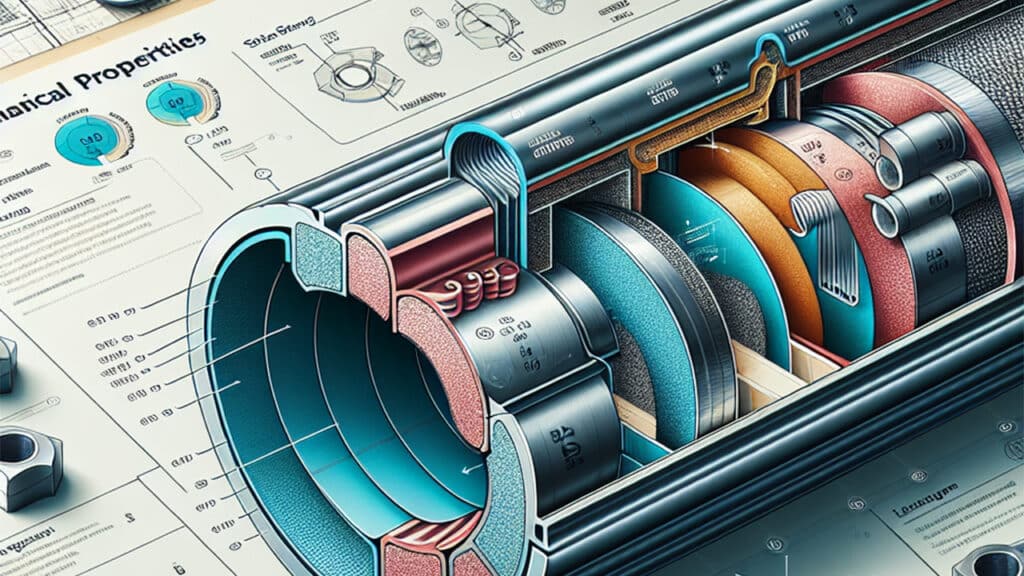

Mechanical Properties

The standard specifies the mechanical properties of the pipes, including tensile strength, yield strength, and elongation, ensuring they meet the required performance criteria.

Testing Methods

ASTM A53/A53M-02 includes various testing methods to ensure the quality and reliability of the pipes, such as hydrostatic testing, nondestructive electric testing, and visual inspection.

ASTM A106-02a

High-Temperature Service

ASTM A106-02a pertains to seamless carbon steel pipes for high-temperature service. These pipes are commonly used in refineries and plants where gases or fluids are transported at high temperatures and pressures.

Material Specifications

The standard specifies the chemical composition and mechanical properties of the pipes, ensuring they can withstand high temperatures and pressures.

Common Applications

ASTM A106-02a pipes are used in various high-temperature applications, including power plants, petrochemical plants, and industrial boilers.

ASTM A333/A333M-99

Low-Temperature Service

ASTM A333/A333M-99 specifies seamless and welded steel pipe for low-temperature service.

Seamless and Welded Steel Pipe

The standard details the chemical composition and mechanical properties of the pipes, ensuring they are suitable for low-temperature applications.

Mechanical Properties

These pipes are used in various industrial applications, such as pipeline construction and transportation of fluids, due to their strength and durability.

ASTM A335/A335M-03

Ferritic Alloy-Steel Pipe

ASTM A335/A335M-03 details seamless ferritic alloy-steel pipe for high-temperature service.

High-Temperature Service

The standard specifies the chemical composition and mechanical properties of the pipes, ensuring they are suitable for high-temperature applications.

Industrial Applications

These pipes are used in various industrial applications, such as power plants and petrochemical plants, due to their strength and durability.

Practical Applications of ASTM Standards

Oil and Gas Industry

Pipeline Construction

ASTM standards are crucial in the oil and gas industry, particularly for pipeline construction. These standards ensure that the pipes used are of high quality, reliable, and can withstand the harsh conditions of oil and gas transportation.

Material Selection

Selecting the right material is essential in the oil and gas industry. ASTM standards provide guidelines for material selection, ensuring that the pipes used are suitable for the specific application and can withstand the required pressures and temperatures.

Construction Industry

Structural Applications

In the construction industry, ASTM standards ensure that the steel tubes and pipes used in structural applications are of high quality and can withstand the required loads and stresses.

Quality Assurance

ASTM standards provide guidelines for quality assurance, ensuring that the materials used in construction meet the required performance criteria and are reliable and durable.

Manufacturing Industry

Process Piping

In the manufacturing industry, ASTM standards ensure that the pipes used in process piping are of high quality and can withstand the required pressures and temperatures.

Material Specifications

ASTM standards provide guidelines for material specifications, ensuring that the pipes used in manufacturing meet the required performance criteria and are suitable for the specific application.

Power Generation Industry

High-Temperature Applications

In the power generation industry, ASTM standards ensure that the pipes used in high-temperature applications are of high quality and can withstand the required temperatures and pressures.

Performance Standards

ASTM standards provide guidelines for performance standards, ensuring that the materials used in power generation meet the required performance criteria and are reliable and durable.

Conclusion

Understanding ASTM standards for steel tubes and pipes is crucial for ensuring quality, reliability, and compliance in industrial procurement. These standards provide guidelines for material specifications, testing methods, and quality assurance, helping procurement managers, engineers, and project managers make informed decisions. Adhering to ASTM standards ensures that the materials used in industrial applications are of high quality, reliable, and can withstand the required pressures and temperatures. As technology advances, ASTM standards will continue to evolve to incorporate new materials, testing methods, and quality assurance measures. Staying up-to-date with these standards is crucial for ensuring the quality and reliability of industrial materials.

Summary of Key Points

Understanding ASTM standards for steel tubes and pipes is crucial for ensuring quality, reliability, and compliance in industrial procurement. These standards provide guidelines for material specifications, testing methods, and quality assurance, helping procurement managers, engineers, and project managers make informed decisions.

Importance of Adhering to ASTM Standards

Adhering to ASTM standards ensures that the materials used in industrial applications are of high quality, reliable, and can withstand the required pressures and temperatures. This is crucial for ensuring the safety and reliability of industrial processes.

Future Trends in ASTM Standards

As technology advances, ASTM standards will continue to evolve to incorporate new materials, testing methods, and quality assurance measures. Staying up-to-date with these standards is crucial for ensuring the quality and reliability of industrial materials.

FAQs

What are ASTM standards?

ASTM standards are guidelines developed by the American Society for Testing and Materials to ensure the quality, reliability, and performance of materials used in various industries.

Why are ASTM standards important in industrial procurement?

ASTM standards provide guidelines for material specifications, testing methods, and quality assurance, helping procurement managers, engineers, and project managers make informed decisions and ensure the quality and reliability of materials used in industrial applications.

What is the difference between seamless and welded steel pipes?

Seamless steel pipes are made from a solid piece of steel, while welded steel pipes are made by welding together pieces of steel. Seamless pipes are generally stronger and more reliable, while welded pipes are more cost-effective and suitable for lower-pressure applications.

How do ASTM standards ensure the quality of steel tubes and pipes?

ASTM standards provide guidelines for material specifications, testing methods, and quality assurance, ensuring that the materials used in industrial applications meet the required performance criteria and are reliable and durable.

What industries use ASTM standards for steel tubes and pipes?

ASTM standards for steel tubes and pipes are used in various industries, including oil and gas, construction, manufacturing, and power generation.

How can I stay up-to-date with ASTM standards?

Staying up-to-date with ASTM standards can be done by regularly checking the ASTM website, subscribing to industry publications, and attending industry conferences and seminars.