The Future of Pipe Manufacturing: Key Trends and Innovations for 2024

As we look to the future of pipe manufacturing, the industry is on the cusp of significant transformation. Emerging technologies, materials, and sustainability efforts are reshaping how pipes are produced and used across industries.

Federal Steel Supply, a leader in pipe distribution, is keeping a keen eye on these developments to ensure our clients benefit from the latest innovations.

Here are some key trends and innovations that will define the future of pipe manufacturing.

1. Technological Advancements in Pipe Manufacturing

3D Printing: Customization and Efficiency

AI algorithms are revolutionizing maintenance protocols in steel plants. Traditionally, equipment breakdowns could lead to costly downtime. AI changes this by analyzing data from machinery sensors in real time to predict when components are likely to fail. This predictive maintenance approach minimizes unplanned downtime and reduces maintenance costs.

For Example:

Implementation of AI in predictive maintenance led to a 15% reduction in unplanned downtime.

Artificial Intelligence (AI)

Smart Design and Production AI is another game-changer for pipe manufacturing, particularly in optimizing designs and predicting performance.

By analyzing vast datasets from previous installations, AI can identify patterns in how pipes perform under various conditions, such as pressure fluctuations or temperature extremes. This predictive capability enables the creation of more efficient, durable pipe systems tailored to specific industries like oil and gas, water treatment, and chemical processing.

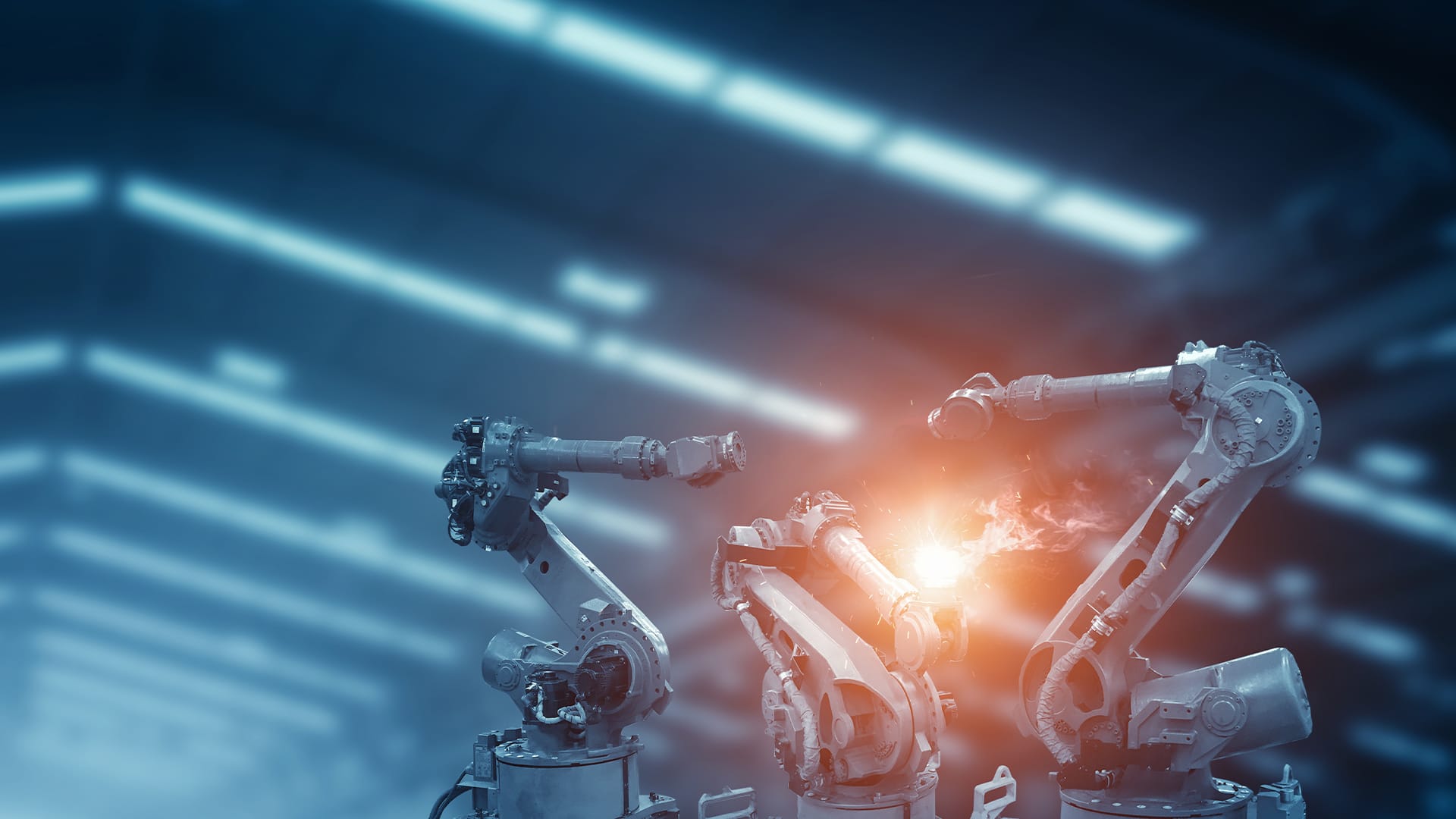

Robotics and Automation

Precision and Safety Automation through robotics is streamlining many aspects of pipe fabrication, from cutting and welding to inspection. Robots equipped with advanced sensors can handle intricate tasks with unparalleled precision, reducing the risk of human error.

In addition, robotic systems enhance safety in manufacturing environments, particularly in hazardous conditions such as high temperatures or chemical exposure.

IoT and Smart Piping Systems

Real-Time Monitoring The integration of the Internet of Things (IoT) into piping systems is making smart infrastructure a reality. Sensors embedded within pipes can provide real-time data on flow rates, pressure, temperature, and even leak detection.

This technology is critical for industries where failure is not an option, such as oil refineries or nuclear power plants, enabling predictive maintenance and minimizing costly downtime.

Stay informed with Federal Steel Supply. If you're interested in learning how these trends can impact your next project, contact our experts today.

Whether it's custom solutions, sustainable materials, or cutting-edge technologies, we are here to help you navigate the future of pipe manufacturing.

Get started by Requesting a Quote or contact us at (800) 325-1584.

2. Materials Innovation: Stronger, Lighter, and Greener

Advanced Composites and Polymers

As sustainability becomes a central focus, manufacturers are exploring the use of advanced materials such as polypropylene, HDPE (High-Density Polyethylene), and fiberglass-reinforced plastics. These materials offer superior corrosion resistance, chemical durability, and flexibility compared to traditional steel or PVC pipes.

Additionally, they are more environmentally friendly, often incorporating recycled materials or designed for longer life cycles.

Sustainable Materials

A Push for Green Manufacturing There is an increasing demand for eco-friendly materials like recycled steel and low-carbon alloys in pipe manufacturing. These materials not only reduce the environmental impact of production but also align with global sustainability initiatives.

For instance, the use of green materials in pipe systems helps companies meet regulatory requirements and enhances their corporate social responsibility (CSR) profiles.

3. Sustainability Efforts: Eco-Friendly Manufacturing Processes

Recycling and Circular Economy Practices

The pipe manufacturing industry is making strides toward more sustainable production methods. One significant initiative is the adoption of circular economy principles, where materials are reused and recycled to minimize waste.

For example, many manufacturers are now incorporating scrap metal into their production processes, reducing the need for new raw materials and cutting down on emissions.

Energy Efficiency and Carbon Reduction

Manufacturers are also focusing on reducing the carbon footprint of their operations. Innovations like electric arc furnaces (EAFs) and advancements in heat recovery systems are helping companies produce pipes more efficiently, consuming less energy while cutting emissions.

As a result, the industry is seeing a move toward greener production techniques that align with global carbon reduction goals.

Stay informed with Federal Steel Supply. If you're interested in learning how these trends can impact your next project, contact our experts today.

Whether it's custom solutions, sustainable materials, or cutting-edge technologies, we are here to help you navigate the future of pipe manufacturing.

Get started by Requesting a Quote or contact us at (800) 325-1584.

4. Evolving Manufacturing Processes

Modular Fabrication

Efficiency in Assembly Modular fabrication techniques are becoming increasingly popular, allowing for the offsite production of pipe components in controlled environments. This method enhances quality control and reduces on-site labor, making installation faster and more cost-effective.

Modular piping is especially beneficial in large-scale projects, such as oil refineries or chemical plants, where time and precision are critical.

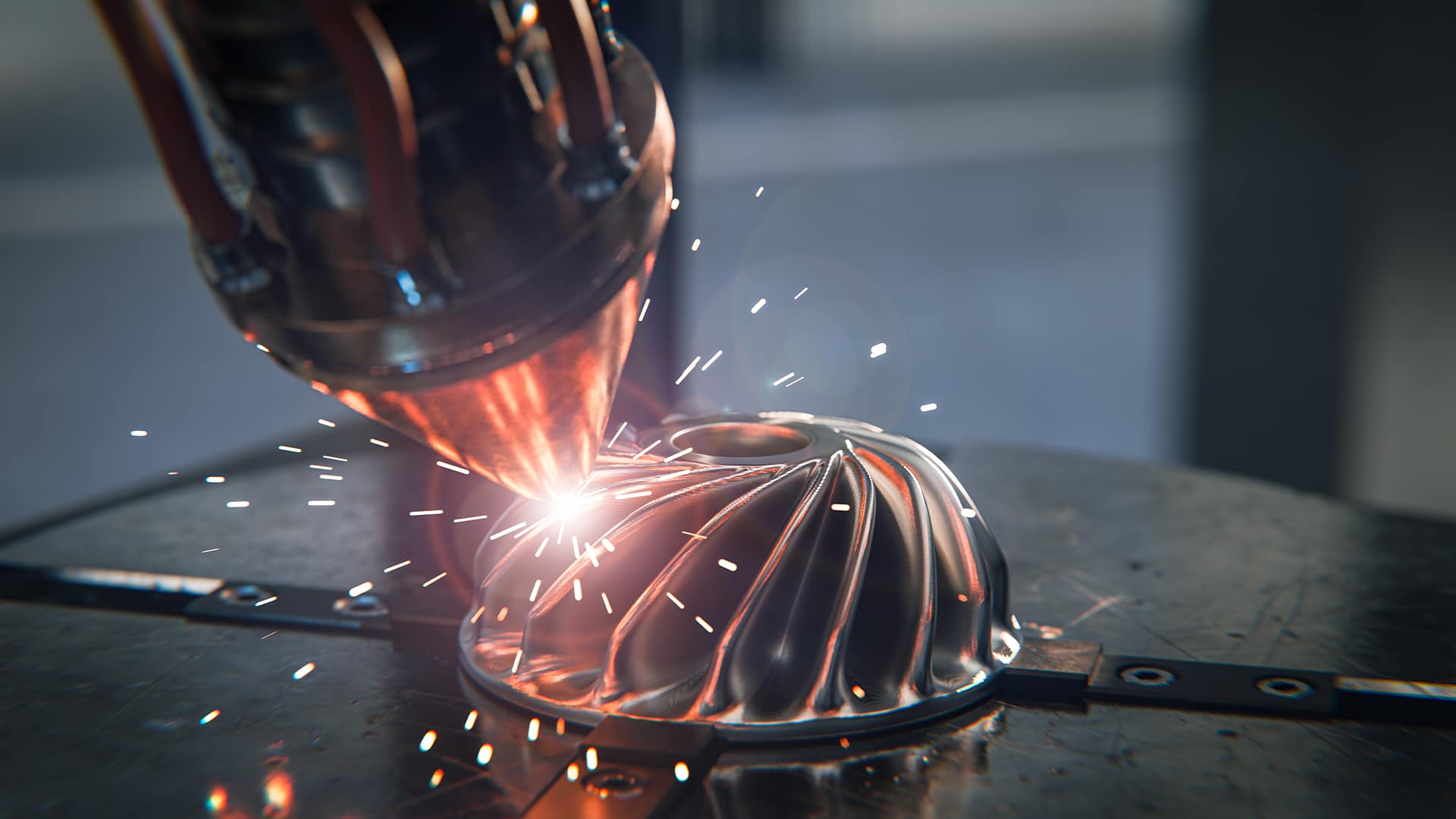

Automated Welding Systems

Reducing Human Error Automated welding systems are revolutionizing the assembly of welded pipes. These systems provide consistent, high-quality welds that are critical in high-pressure environments such as power plants or offshore oil platforms.

With automation, manufacturers can reduce the chances of human error, ensuring pipes meet the stringent standards required for such applications.

Building Information Modeling (BIM)

Collaborative Design Building Information Modeling (BIM) is enhancing collaboration between engineers, contractors, and manufacturers by offering detailed 3D models of piping systems.

BIM allows for accurate planning, improved visualization, and precise measurements, reducing the likelihood of errors and rework during installation.

5. The Road Ahead: What to Expect in Pipe Manufacturing

The future of pipe manufacturing is being shaped by these technological innovations, material advancements, and sustainability initiatives. With increased automation, smarter materials, and greener production processes, the industry is poised for a new era of efficiency and environmental responsibility.

At Federal Steel Supply, we are committed to staying ahead of these trends, ensuring our clients benefit from the latest developments in the field.

Frequently Asked Questions

AI optimizes pipe design by analyzing large datasets to predict performance and improve durability, reducing waste and improving efficiency.

3D printing allows for the creation of customized pipe designs directly at construction sites, reducing assembly time and material waste.

Advanced composites like polypropylene, HDPE, and fiberglass-reinforced plastics are gaining popularity due to their durability and environmental benefits.