For decades, the steel industry has battled with environmental friendliness. The world’s leading steelmakers are bustling to reduce carbon emissions by revolutionizing their technologies. Currently, the steel industry is one of the top three most prominent carbon dioxide producers.

Historically, steel producers’ embrace of technology and innovation is what has kept this industry alive. Now, they’re looking for new solutions to meet demanding emerging clients–in the energy space.

New Environmental Guidelines for the Steel Industry

Lowering carbon emissions is every company’s new target. Undoubtedly, there’s a progression from both consumers and companies to move from coal and oil into natural gas and other greener solutions.

For steel producers, this means it’s time to make significant transitions. The steel industry’s high carbon footprint is undeniable. Manufacturers are searching for solutions to lower their contribution to CO2 emissions. That’s where the Environmental Protection Agency (EPA) stepped in. The EPA proposed and approved a new set of guidelines to control the steel industry emissions.

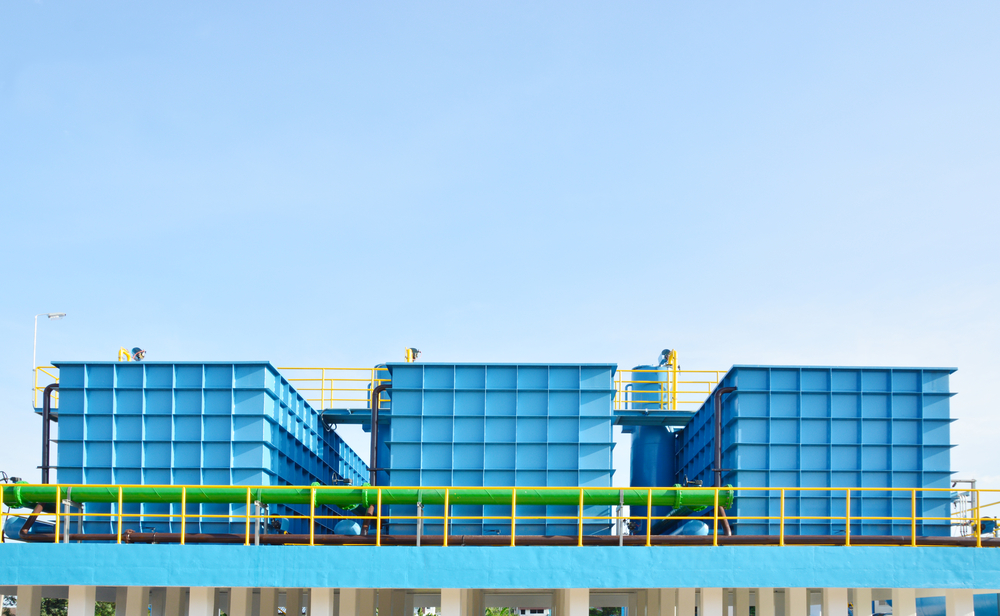

Under this new provision of regulations, iron and steel facilities will face penalties for discharging directly to surface waters or indirectly through publicly owned treatment works. Instead, the EPA will require companies to search for permits or other control mechanisms of indirect discharges.

Transitioning to “Green Steel”

Steel companies are well aware of the economic risk of not reducing their environmental impact. With both consumers and governments becoming more earth-oriented, the transition to ‘green steel’ is a multi-billion dollar opportunity they can’t miss.

In the steel industry, ‘green steel,’ or the equivalent of decarbonization in this sector, seems to be the best route to facilitate and accelerate the transition. Beyond altering the material itself, the idea is to look at processes. Although ‘green steel’ is an easy label to adapt to, it can still be hard to achieve.

The call is to produce “carbon neutral” steel using hydrogen from renewable energy sources instead of coal. Of course, a label is nothing without the right regulations and organizations that ensure manufacturers follow these new guidelines. So far, countries like Chile and Germany have very ambitious goals to reach ‘green steel’ by 2025 as they invest in transitioning to hydro-powered solutions.

How the Decarbonization Process Works

Another model is the decarbonization process proposed in Europe that expands upon the Paris Agreement guidelines. Multiple programs are currently in testing to decrease carbon footprint within the steel industry. These decarbonization processes involve technology strategies such as:

BF/BOF efficient programs: These programs decrease production losses by optimizing blast furnace (BT) burden by reducing coal use and increasing fuel injection using natural gas, biomass, or hydrogen as alternatives.

Biomass reductants: This decarbonization process uses biomass, such as heated energy cane or pyrolyzed eucalyptus primarily, as an alternative reductant or fuel. In biomass-rich territories like South America and Russia, this could be a game-changer for the industry.

Carbon capture and usage: In this method, emissions are used to create new products for the chemical industry, such as bioethanol. While this technology is premature and yet to be proven economically, it could be a viable solution for many companies.